Mohamed Osmani, a partner on the ICEBERG project, is Professor of Sustainable Design and Construction in the School of Architecture, Building and Civil Engineering at Loughborough University, UK.Professor Osmani’s research and collaborative interdisciplinary projects cover life cycle sustainable design and construction issues associated with sustainable design and construction innovation; best practice and change management; circular economy; material resource efficiency; designing out waste; anthropogenic resource classification; construction and demolition waste recovery and optimisation; and the impact of building information modelling, virtual prototyping and blockchain on sustainable project performance.

Loughborough University

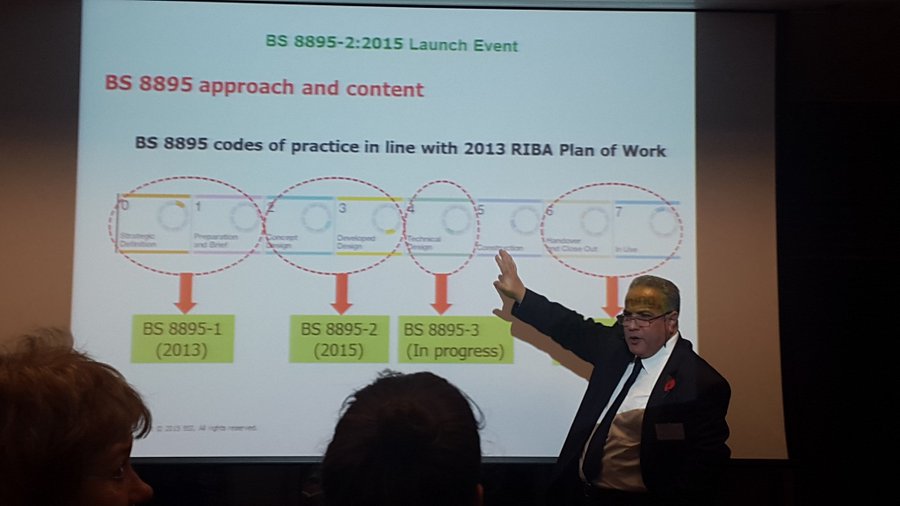

Professor Osmani is currently leading five international panels and expert groups, including BS 8895 series, and IWWG Construction and Demolition Task Group. He is a member of numerous UK and international advisory boards and expert groups, including the UNECE Expert Group on Anthropogenic Resources and the UK Government Green Construction Board Resources & Waste Task Group, entrusted with developing a roadmap towards achieving zero avoidable waste in the construction sector by 2050.

What specific activities are you working on as part of the ICEBERG project?

We are involved in all the ICERBERG work packages. In terms of specific activities, we are leading the development and validation of advanced technologies for the purification and processing of gypsum waste from end-of-life plasterboards and synthetic gypsum. We are working closely with British Gypsum, part of the Saint-Gobain group (the UK’s leading manufacturer of plasterboard), and ENVA (a leading plasterboard recycler in the UK and Ireland).

Our ongoing collaborative work in the ICEBERG project includes: (1) optimisation of end-of-life gypsum treatment at laboratory scale; (2) homogenisation after the treatment to achieve low variability in purity levels; (3) upscaling purification treatment at a semi-industrial level; (4) adjusting formulations and pre-industrial prototypes of circular plasterboards; (5) demonstrating the application of novel circular plasterboards using 35% recycled gypsum in a refurbishment project; and (6) performing life cycle assessment and life cycle costing of the resulting circular plasterboards.

What do you expect ICEBERG to contribute to the construction and demolition sector? Describe some significant achievements.

ICEBERG has developed purification treatments based on hydrocyclone separation and acid leaching to increase the recycled gypsum content in new plasterboards from the current 10-15% recycling rate to 35%

Gypsum is the main constituent of plasterboards used in building applications. Although gypsum can be recycled indefinitely, the amount of recycled gypsum that can be incorporated into new plasterboards is limited by the presence of impurities, introduced with the use of additives and the formulation of the lining paper. As these soluble impurities relocate, they interfere with the bonding properties of the gypsum particles which, in turn, affect the mechanical properties of the plasterboards. Therefore, ICEBERG has developed purification treatments based on hydrocyclone separation and acid leaching to increase the recycled gypsum content in new plasterboards from the current 10-15% recycling rate to 35%. Our main achievements to date are producing recycled gypsum with high purity levels of 96-97% at laboratory scale, which could potentially be used by plasterboard manufacturers with zero or minimal further pre-conditioning.

What would you say are critical aspects of this sector where changes should be introduced to progress towards circularity? In your opinion, what are the technical and other difficulties that need to be overcome for this transformation?

The construction industry is by far the greatest consumer of resources and producer of waste when compared to other economic sectors. While the sector has successfully achieved high recycling rates, most waste is downcycled. As such, the value, quality, and functionality of recycled products are lower than their original counterparts. Moreover, the resources that the sector uses derive largely from primary sources, and material costs are rising. A paradigm shift towards the use of sustainable construction materials in the Circular Economy (CE) will require systemic change based on new business models and a full consideration of the impacts. This will be not be possibly only by means of one-off decisions for individual projects or businesses or a generic aspirational approach without specific interventions with evidenced effects.

Additionally, insufficient skills can also create challenges to identifying, assessing and implementing CE solutions. This is compounded by an immature market for reused and secondary construction materials, insufficient data and the lack of a coherent infrastructure for collecting, sorting, and reprocessing wastes, as many companies rely on external providers to create closed loops. This can result in a lock-in effect, where barriers result from inertia and the dominance of existing technologies and systems.

Policymakers and the industry are beginning to recognise these concerns and developing CE strategies, action plans and roadmaps, though progress is slow. Specific sector frameworks and technological innovation are to CE are currently lacking in the construction sector, even though the various benefits of their application are evident. As such, ICEBERG is addressing these bottlenecks through the design, development, and validation of new technologies to reduce primary raw material demand, enable the circularity of end-of-life construction materials, and create economic value while improving environmental and social impacts.

In recent years solutions have been developed and tested that could be of real use. Is there an actual transfer of this knowledge to companies in the sector? It seems that the business-university relationship is crucial, but is it properly articulated in order to make this flow of knowledge effective?

Knowledge sharing, co-creation, and transfer mechanisms in relation to Circular Economy best practice and enabling tools and technologies are critical

University-business relationships are playing an increasingly important role in CE knowledge transfer. Indeed, knowledge sharing, co-creation, and transfer mechanisms in relation to CE best practice and enabling tools and technologies are critical. These are being taken up in a growing number of CE approaches and strategies adopted mainly by several major European construction organisations. However, this is currently in the embryonic stage and still far from being widespread in the construction sector. Hence, the ICEBERG approach is guided by a business-university/research knowledge value co-creation of CE solutions via scientific and socio-economic understanding and technological basis for the development and implementation of circular building materials and technologies, and policy recommendations that will support the transition to a truly CE in the construction sector. This will be made possible via partnership agreements, which will provide a platform for the replication of these relationships and the resulting CE solutions in other universities and companies in the construction sector, and potential transfer to other sectors.

Do you believe that a circular construction within the framework of the circular economy is possible in the medium term?

There is great potential for cycling of construction products and materials at higher value based on secondary raw material input, as well as demand and impact reduction at all stages of their lifecycles through alternative circular materials and practices. At present, many construction sector initiatives aim at reducing the use of primary raw materials and associated emissions. As these gradually become successful, circular construction materials will become more significant. That said, circular construction changes to the practices of businesses throughout the whole value chain and system are required to remove barriers, provide better tracking of material flows, and create market support for the adoption of new circular materials, technologies, and systems, as well as changes in policy and regulation that will support these new circular business practices in the construction sector.

Undeniably, far greater emphasis will need to be placed on transferrable business models in the future if construction businesses are to lead the shift from linear economy to CE. Equally, more evidence is required on how transitioning to CE practices is likely to affect business performance, investment decisions, innovation, and employment. These issues are being considered in the ICEBERG project, aiming at improving the economic viability and market potential of end-of-life building materials, by providing designers, manufacturers, builders, and recyclers with advanced smart and technological CE solutions leading to more efficient, competitive processes, higher traceability, market acceptance, and higher levels of material circularity.