GAIKER is already working on the development of an automated highly flexible and mobile prototype for processing C&DW

One of the Spanish partners of ICEBERG project, GAIKER (Technological Centre) is involved in the development of an automated highly flexible and mobile prototype sorting line based on hyperspectral imaging (HSI) for stony mixtures and its adaptation for processing other C&DW streams (mixed PU/PIR foams and gypsum) as well.

In this regard, GAIKER began the initial planned activities aiming the selection and acquisition of a laboratory HSI system for the analysis of representative real stony samples from demolition sites. The hyperspectral data obtained will be further used to develop a new classification method, based on deep learning techniques, for the identification and categorization of the input materials into three outputs attending to their composition: grey fraction (composed by cement-based materials), red fraction (composed by ceramics), and impurities (e.g. plastics or gypsum).

The quality of the hyperspectral data will determine the ability and efficiency of the upcoming classification algorithm. Therefore, the choice of the HSI system has been a thoroughly considered and justified decision. The hyperspectral cameras available on the market that best fit the objectives of the project have been evaluated. This assessment has been based on their technical characteristics and the experience gained by GAIKER in a previous European project called HISER.

Hyperespectral camera

The acquired camera covers a wide range of wavelength in the SWIR region, including those values which attained better results within the previous research carried out in HISER project. Additionally, its sensor combines very high acquisition speeds with very high spatial and spectral resolutions and features superior image quality in terms of image sharpness and low distortion.

Other remarkable characteristics of the acquired instrument are the following: Minimized and equalized point spread function across the FOV and throughout the wavelength range; good matching of point spread function with pixel size; low stray light; low smile effect and spectral keystone effect and low polarization dependence.

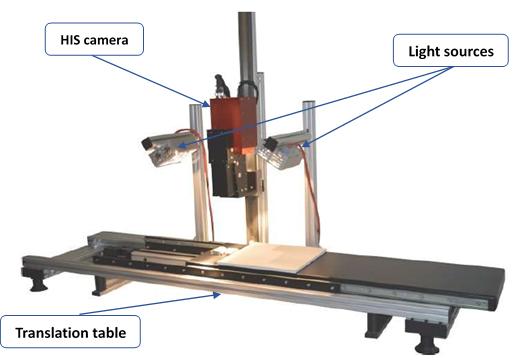

Together with the camera a convenient set-up for analyzing samples has been also procured, with a dedicated rack for accommodating an adjustable platform for the camera, the illumination system, and a sliding translation table. The HSI system is illustrated in the opening picture.

The classification method built upon the results from the HSI analysis will be later implemented in the automated mobile smart sorting prototype that will be developed to validate, under real operational conditions, the envisioned cost-effective advanced production system of high-purity secondary building materials.

The hyperspectral data obtained will be further used to develop a new classification method