Delf University of Technology has tested a RFID-based Integrated Material Passport System for recycled concrete aggregates.

Closing the concrete loop prevents loss of value of concrete aggregates and has environmental benefits. In some EU member states, information systems that store data on material stocks and flows, known as material passport systems –or tracing systems–, are considered vital in the transition to a circular (construction) economy. However, the digital representation of the physical world is only as good as the translation into digital data.

The opportunities and challenges of the proposed Radio Frequency Identification / RFID-based Integrated Material Passport System (IMPS) for concrete aggregates have been studied in the Netherlands.

RFID tags are electronic devices that store digital information. The technology was first developed during the 1970s in the United States for an automated highway toll system but quickly spread to other sectors around the globe. Its current uses include tracking goods in supply chain management, contactless payment systems, access and security management, for example.

An RFID tag consists of at least a microchip that stores and processes information, an antenna to send/receive signals, and a means of powering the tag. Passive RFID technology uses the transmitting signal of the reader as an energy source, meaning no batteries in the tag are required, which decreases the size, complexity, and cost of the tags. However, passive tags require a stronger signal than active tags to power the device, and the reading range is limited when reading through metal or liquid.

Several authors have suggested using RFID tags to identify and track construction materials. Wang (2008) integrated RFID tags in concrete for tracking and storing information about concrete samples in a lab environment. However, no such system has been used to collect and trace the quality of recycled concrete aggregates yet.

Innovative proposal

The RFID system –along with the quality assessment system and the tracing system– studied is part of a patented methodology/process whose title is: “Method and system to convert demolished concrete into a readily recyclable product” (patented by Delft University of Technology. Application Number N2021751). It proposes to combine an in-line Laser-Induced Breakdown Spectroscopy (LIBS) quality assessment of recycled concrete coarse aggregates through LIBS together with a RFID writing module to check the source and properties of the resulting concrete.

The exploratory study at the TU Delft (Delf University of Technology) regards the use of modern RFID technology as a basis for a material passport for concrete. The study assessed the function of a passive RFID tag in recycled concrete aggregates concrete cubes. It examined the properties of the RFID technology in terms of the physical limits of RFID technology when incorporated into gravel and concrete. The examination includes the range and angles at which the tags can be detected.

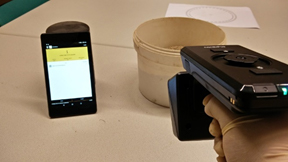

A RFID reader model was used for the experiment at its maximum capacity (1000mW) to provide maximum power to the passive RFID tags. The reader works in the ultra-high frequency range 868 MHz, which meets European standards. Small (5x5x3mm) passive RFID tags were selected because they do not require an internal energy source. They have a ceramic outer shell, which make them more resilient to external forces.

After casting concrete samples, the maximum reading ranges were determined. Once demolded (24 hours after casting), the RFID tags were checked for survivability. Because water decreases the RFID signal strength, the first maximum reading range measurements took place after sufficient drying, 72 hours after casting.

RFID systems have not yet been used to collect and trace the quality of recycled concrete aggregates

NORDIC ID EXA51e RFID reader/writer and Abracon ART915X050503OP-IC passive RFID tags. |  Simulating the handling of Abracon ART915X050503OP-IC passive RFID tags. |

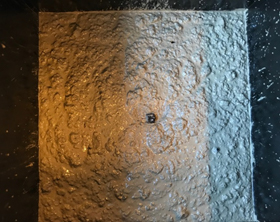

Embedding Abracon ART915X050503OP-IC passive RFID tags in a concrete cube. |  Embedding Abracon ART915X050503OP-IC passive RFID tags in a concrete cube. |

Assessing the readability of Abracon ART915X050503OP-IC passive RFID tags in concrete aggregates. |  Assessing the readability of Abracon ART915X050503OP-IC passive RFID tags in concrete aggregates. |

| Assessing the readability of Abracon ART915X050503OP-IC passive RFID tags in a concrete cube. |

The results of the extensive performed tests can be summarized as follows:

- The average increase in readability (over 25 days) due to the decreasing water content has been observed.

- The heavier the handling of the RFID containing aggregates, brings about a reduction in readability.

- Maximum average reading range ≈ 32cm (+ 81% in 25 days).

Similar results have been observed for the rectangular prisms. However, the maximum average reading range is 22 cm (probably due to the steel rebars disturbance effect).

Concerning the quality assessment and tracking system, the TUDelft team has been working on the development of the LIBS-based facility (other sensors are going to be taken into consideration). The spectra of the most common EBM’s contaminatns have been acquired by the LIBS-based facility and are currently being analysed. The systems for the transferring of information (both material quality as well as demolition project details) to the tracing tags and the CTP are being designed. The figures below show the facility already available in the R&R Lab. To facilitate the transportability, the facility is made as compact as possible and included in a container.

LIBS-based quality assessment and tracking facility. |  LIBS-based quality assessment and tracking facility acquiring the bricks’ spectra. |