- The aim is to offer innovative circular economy-based solutions for producing high-value materials from the most common construction and demolition waste (C&DW).

- The project, which kicked off in 2020 and will continue until 2024, has a budget of €15,667,498, of which the European Union is contributing €12,997,935 from the Horizon 2020 Research and Innovation Framework Programme.

- Six Basque organisations are involved: Ihobe – the Basque Government’s Public Environmental Management Company, Fundación TECNALIA Research & Innovation (which will coordinate the consortium), GAIKER Technology Centre, and the companies, Serikat, Lezama Demoliciones and Viuda de Sainz.

Bilbao, 6th October 2022 As of yesterday, the Basque Country is the venue for the general assembly of partners of the ICEBERG project, which is headed by TECNALIA Research & Innovation and in which 35 public and private organisations from ten European countries are involved. The meeting, organised by Gaiker Technology Centre, kicked off yesterday in Zamudio and will provide a chance to review the progress made over the first two years of work.

The European ICEBERG project – acronym for Innovative Circular Economy Based solutions demonstrating the Efficient recovery of valuable material Resources from the Generation of representative End-of-Life building materials – is funded by the European Union as part of the Horizon 2020 Research and Innovation Framework Programme (contract No. 869336). It aims to address the circularity of the most commonly used materials in construction, ranging from the recovery and recycling of construction and demolition waste (CDW), to the development of more sustainable products.

The General Assembly started yesterday with some presentations on different topics led by the partners, such as, legislation, policies and standards (VTT), social attitudes towards circularity of building products (IHOBE), standardization activities (RINA Prime) or pre-demolition audits and traceability systems (Tracimat). The meeting served to share knowledge, research and progress made in the first two years of the ICEBERG project. Tomorrow´s agenda also includes several workshops on barriers for the uptake of ICEBERG solutions that will be led by partners from Tracimat, VTT and Loughborough University.

The objective of the ICEBERG project is to design, develop and validate innovative recycling systems and technologies, to make it possible to produce high-value recovered materials, that have a low level of impurities (less than 8%) and are safe. Validation will be carried out on an industrial scale by means of six case studies in different locations in Europe, covering the circularity of concrete, ceramics, wood, plaster, insulating foams and super-insulating materials. It also seeks to improve the reliability and acceptability of recycled materials from construction waste.

MOBILE SEPARATION UNIT

GAIKER Technology Centre will help develop the mobile unit for the automatic separation and classification of CDW. In this case, the Basque companies, Lezama Demoliciones, Serikat and Viuda de Sainz participate by providing their expertise and collaborating in the development of the reverse logistics support tools and validating all the solutions in a local case study (of the 6 case studies included in the project, one will be run from the Basque Country).

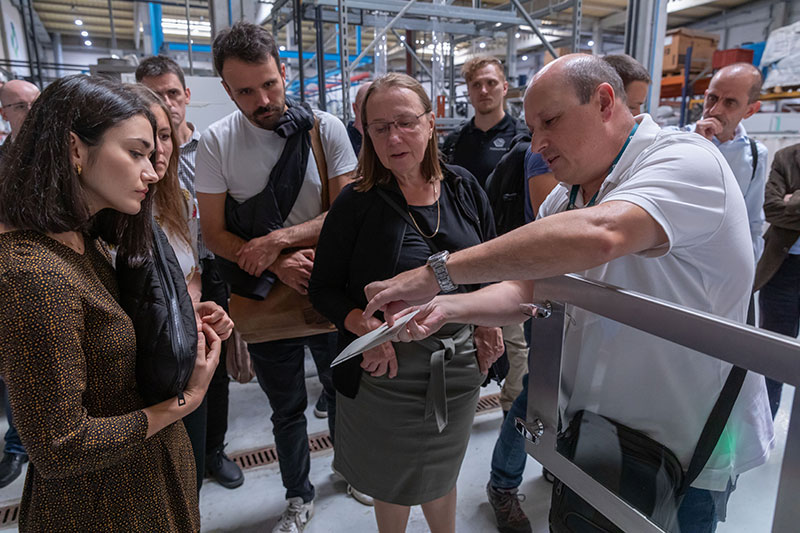

Representatives of the 35 organisations involved visited Gaiker’s facilities yesterday to see the automatic material recognition equipment using hyperspectral sensors and artificial intelligence algorithms, which is being brought to industrial scale by LENZ Instruments and will be validated in several of the case studies over the coming months, whereby one of them is led by Viuda de Sainz.

ICEBERG

The project will last for four years and has a budget of 15,667,498 euros, of which the European Union is providing 12,997,935 euros. In the first half of the project, tools and technologies are being developed to improve the traceability, identification, separation, recycling and reuse of materials from C&DW. The second part of the project will be dedicated to demonstrating these solutions in six case studies, by analysing their economic and environmental impact and their impact on workers’ health.